Quality Alert Triggers in Odoo v10

Quality Alert Triggers in Odoo v10 are used to automatically generate alerts when certain conditions occur in your business activities. These triggers help to maintain product quality by establishing rules for operations such as product receipt, manufacturing, and inventory management.

If an issue emerges, such as a product that does not satisfy quality standards, an alert is generated automatically. This enables the team to be instantly notified and take action to resolve the issue, resulting in consistent product quality. Quality Alert Triggers enable firms to be proactive and reduce quality issues throughout various processes.

So we saw in the previous instance how we raised a Maintenance issues. Now we will go through steps when a quality issues is raised.

From the workcenter control panel on tablet we can issue a Quality alert and it gets registered and alerts Quality Team.

The quality team then addresses the issue and puts a note after appropriate tags and priority have been marked. Also, notes can be put under Corrective/Preventive Actions. Again through the Mail gateway all involved in the process will receive mail alerts and who so ever is responsible will act on it.

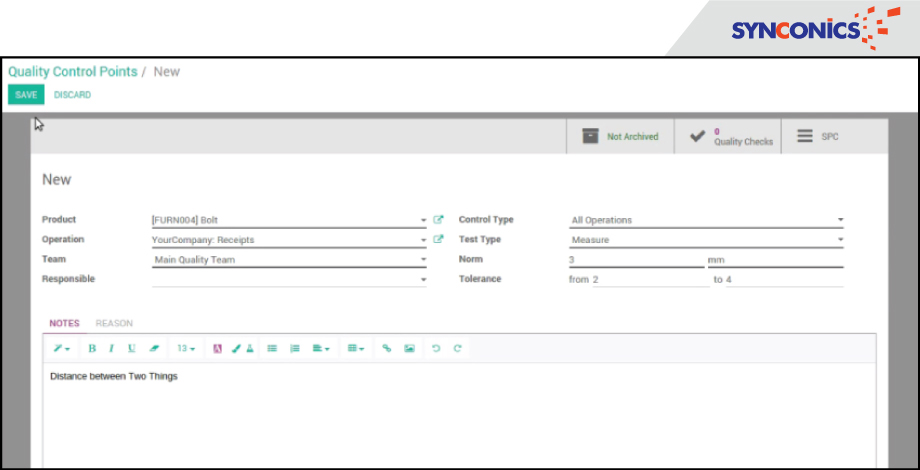

Once the root cause has been identified you can set up a preventive action and mark it so whenever that particular part/machinery arrives from the supplier at fault the inventory team will check for those marked issues. So a control point is created with specific set of instructions as deemed necessary and when the company receives that part a check has to be done randomly or periodically.

So now we go to inventory and create a Quality check To Do for that particular part when it arrives. Normally you don’t have to create manually; it comes from the system as we have already defined it earlier.

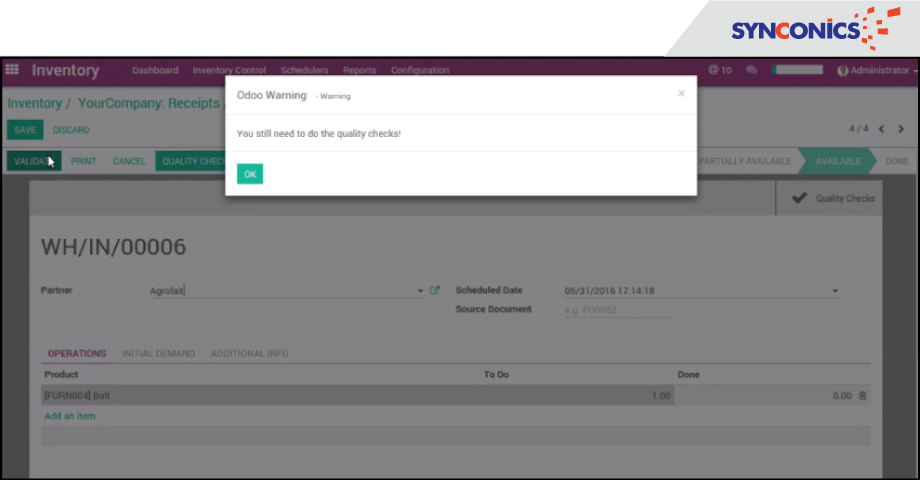

Once we do that, we get a new Quality Checks tab, unless that is done it will not allow validating and accepting that product.

We Started with Quality Alert, Then moved to set up control point, Then had a Quality Check. All very simple compared to having different software for all of them and having to instruct personnel in different departments look out for the same!

After repeatedly getting faulty products from a supplier we decide to change the supplier. It isn’t a simple process, as we have to do an engineering change order. Logistics will have to find a new supplier, engineering will have to redesign the BoM, Manufacturing engineering will have to change the work sheet for worker.

To assist you more please mail us on contact@synconics.com and also explore Synconics.com